Printing: Flexo printing

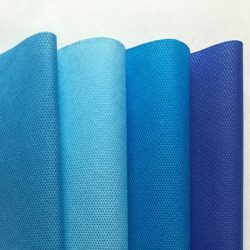

Material : PP

Sealing : Heat seal

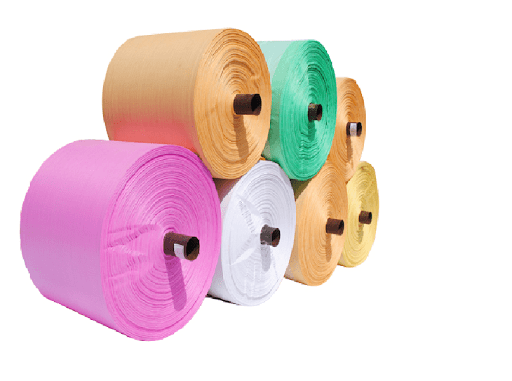

Color: Many color

Size : Customized size

Weight: 60gsm – 150gsm, customized

Lead time : 10-20 days after payment

Price : Contact for accurate pricing

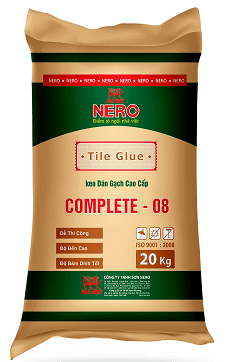

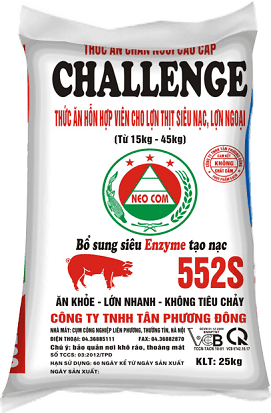

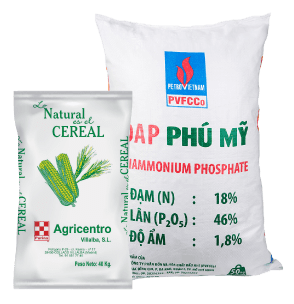

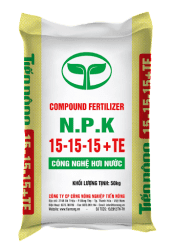

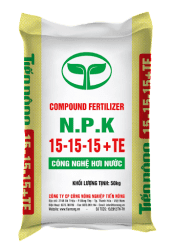

Applications: Agricultural, animal feeds, construction and industrial product packaging, etc.

Customisation: Yes

Origin : Vietnam

MOQ : 30,000 – 40,000 pcs per design

Payment : L/C , T/T, many

Shipping : FCL, many

Factory inspection: HACCP, FSSC 22000 by Intertek, SEDEX SMETA 4P,

QC : Tensile check, load check, print quality check

Supply ability : 120,000 Piece/Pieces per day

Packaging & delivery : Normally 1000 pieces but can customized

Port : Ho Chi Minh City Port

PP woven bag is a type of packaging made from the weaving of woven plastic thread from into a fabric that is then constructed into bags.

It is an indispensable product in almost a multitude of goods exporting sectors like agricultural as an example, given its usefulness and versatility when it comes to storing goods and products. With increasing demand combined with modern technology, PP woven bag is produced with many different types from designs, colors, uses to fit the buyer’s needs.

The main printing technology which PP woven bag manufacturers use commonly is flexo printing technology for simple contents and gravure printing technology for BOPP lamination to produce the sharpest images. In addition, offset printing can be used for products including Kraft/Ford/Couche papers lamination.

PP woven bag has load-bearing effect + PP adhesive layer has a moisture-proof effect, increasing the physical endurance of packaging, waterproofing, moisture-proof.

PP woven bag can be printed flexo up to 6 colors on each side. Addition, PP woven fabric material can be multicolor.

PP woven bag will have the size and amount of fabric suitable for the product load contained in the bag.

Polypropyl woven bag can be folded, bottom folded 3cm. Finished products will be carefully baled, wrapped outside before delivering to customers.

PP woven bag can be laminated on the outside (coated) or laminated inside.

PP woven bag can be laminated OPP combine with gravure printing technology to create packaging samples with high-quality sharp image.

With the above characteristics, PP plastic beads create a durable and safe material to be used as packaging.

This is eventually used to be made into bags and the finished product can be printed and coated depends on the customer’s needs.

Step 1 :

Material prepping

Step 2:

Extruding

Step 3 :

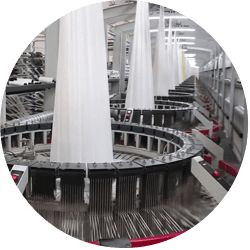

Weaving

Step 4 : Laminated BOPP Gravure/ Flexo Printing

Step 5 :

Coating / Laminating

Step 6 :

Final Product

Step 7 :

End product storing

PP bags with BOPP lamination

No coating which allow the contents to be easily seen

One-side or Two-side Flexo for non-coating PP

The bag can be coated either inside, outside or given a matte coating for better durability or aesthetic purposes.

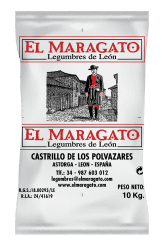

PP bags with Kraft paper lamination

PP woven sack has 1 layer of PP woven laminated with PP plastic to bond. The ends of the bags are not glued or glued with PP strips, fold the brace and sew with cotton thread, together with the angular shaped valve, the valve is constructed in a 1-way, self-locking principle. The bag is printed with 2 sides Flexo with pictures and colors according to customer requirements. The bag withstands loads from 25 - 50 Kg used to pack cement, plaster, taical, flour, chemicals …

PP woven sack has 1 layer of PP woven laminated with PP plastic to bond. The ends are wrapped with rectangular PP adhesive tape, when closing the material will be in the form of cubes, with angle feeding valve, the valve is constructed in a 1-way, self-locking principle. The bag is printed with 2 sides Flexo with pictures and colors according to customer requirements. The bag withstands loads from 25 - 50 Kg used to pack cement, plaster, taical, flour, chemicals …

PP woven sack has high strength and printing ability. The main material is PP resin with high mechanical strength, quite hard but also certain flexibility. Therefore, this product has great durability.

The surface of the package is highly glossy to facilitate printing of sharper colors and textures. So many companies choose PP woven bag to print logo, company name, product name on the package to promote the brand also.

PP woven bag has water, grease, O2 and non-toxic properties so it is friendly to environment. This is also the reason why this product is now commonly used.

PP woven sack can contain, preserve many different products.

PP woven bag is coated with PE film to create a very high adhesion. Therefore, the packaging can be used to contain liquids such as: rubber latex. Ability to move away without tearing due to high strength, no leakage or osmosis.

In addition, with advanced weaving technology and machines, the PP yarns are also woven firmly to make PP woven bag more durable, without tearing.. They can not only be used to preserve simple items, but can also be used to preserve difficult products such as liquids and chemicals. This is one of the outstanding advantages only in PP woven bag.

We have accept customized pp woven sugar bag in our warehouse. They are 100% virgin polypropylene, misprinted bags, never

be used, cheaper and high quality. If you need, contact me: doris. teng 89 Generally, we work on OEM orders, that

means size, weight per bag, loading weight, quantity, printing, etc will depend on you requests.

Option 1: size, mesh, denier, printing;

Option 2: size, GSM, printing;

Option 3: weight pg, per barinting;

Option 4: loading weight, usage, we can design the perfect bag for you.

We are happy to provide the samples to you if we have the identical or similar samples in our warehouse, and they are totally free. But if we haven’t, it’s a pity we cann’t provide. If you insist on samples, we can make the samples for you, but the sample fee must be charged. Generally, 5-7 days for sample making.

The bag are made of 100% virgin polypropylene, they can be used many times. So they are higher than recycled material bags. Our price is flat with the market one. Besides, we will give you the best price on the premise of solid quality. The lead time of mass production will depend on quantity, production art, etc. FYI, 20-30 days for 50,000 pcs bags.

Generally, 10 tons/20 ft container; 24-25 tons /40 ft container

With more than 20 years of experiences, Duong Vinh Hoa never stops itself from updating and innovating to help bring QUALITY – CONVENIENT – ECO-FRIENDLY packaging solution to all customers.

(+84-272) 3900 228

Lot D20-D26, Road No. 3, Hai Son Industrial Zone, Duc Hoa Ha Commune, Duc Hoa District, Long An Province, Vietnam

www.dvhpackaging.com

© Copyright 2019 - DuongVinhHoa Packaging

Chính sách/ưu đãi sẽ được trình bày khi làm việc trực tiếp với khách hàng.