Cement bag which is considered good needs to achieve 3 factors :

The cement bags have 2 types which are composed of one or two layers.

+ The outer layer is a KP complex film (with 1 Kraft paper layer sticking to 1 laminated PP plastic ).

+ The inner layer is Kraft paper.

Packages of Construction materials are usually produced with 50kg material/ bag and cement bags are no exception. But some foreign cement production companies can make some small changes depending on their purposes

Manufacturing and Suppyling packaging products – Duong Vinh Hoa Company is proud to be the pioneer with more than 25 years of expreriences in the construction material packages field. In particular, producing cement bags is the aspect we Duong Vinh Hoa takes special care of, in order to satisfy as much construction industry needs as possible.

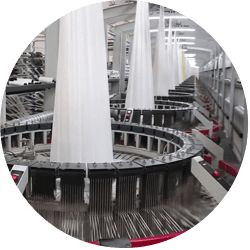

Each package requires different form of production. However, in general, to produce a proper cement bag requires lots of stages and a huge number of different machines.

Cement bag is produced in advanced technology lines and tested strictly before it reaches the customers.

Step 1 :

Plastic granules

Step 2 :

Drawing thread

Step 3 :

Weaving

Step 4 : Laminated with PE or BOPP (If applicable)

Step 5 :

Flexo printing (If applicable)

Step 6 :

Finished product

With huge factory system and modern printing technique, Duong Vinh Hoa produce cement bags in large quanities annually, not only satisfying domestic needs but also being able to export cement bags to other countries.

Our customer system that has been supplying products of construction materials : Sika, Son My Kolor, Kova, Bestmix, GPS Viet Nam, Tan Hoang Minh, Jison, Lotus, NextBuild, Skymax, Nishu,..v..v..

Cement bag quality of Duong Vinh Hoa brand is highly recommended by our customers. It is durable and has high quality inside. Moreover, it is both highly anti-hygroscopic and waterproof.

Also called KP bag – is a ) is a type of packages that is used in construction material industry and has a basic structure: Kraft paper printed flexo according to the design pattern, laminated with white woven PP, folded hip, open mouth or half- open mouth (depending on the packaging method of the customers).

Composition of cement bags that applied Flexo printing:

Offset printing is a printing method in which all the images with ink will be squeezed onto rubber sheets ( also called offset sheets) then the rubber will be squeezed onto the paper surface. When used with quartz printing, this technique prevents water from sticking to paper through the ink way. Offset printing has many advantages so the method is in good books of many manufaturer and applied widely in cement production.

These advantages includes:

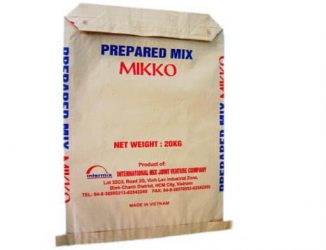

This is a more advance line of packages than the Flexo printing products

Packaging structure is thick and strong, composed of 3 layers : OPP film/paper/woven PP, creating a finished packaging solution, ensuring the products won’t broken during the packaging and transporting process.

The printing quaily is great with clear color, high image quality, lively, highly artistic, impressive and attractive to the customers.

Gravure printing is a concave printing, it means on printed mold, the images or handwriting (called printing elements) are gravured concavely onto the metal surface.

The gravure mold is in the form of a metal axis, made of steel, the surface is laminated with a thin layer of copper, the printing element will be engraved on the surface of the copper layer by acid or by using a shaft engraving machine. After that, the surface of the copper layer will be laminated with a thin layer of chromium for protection.

Gravure printing is used in the printing packaging industry, especially in the production of high quality cement bags.

BOPP cement bag structure :

BOPP cement bags applied gravure printing is used in the construction materials industry because of these features : clear image, anti-hygroscopic and waterproof.

With the mission of bringing optimal and effective packaging solution to the packaging industry in general and construction materials industry in particular, Duong Vinh Hoa has been providing the best quality products that are accredited by international organizations.

With more than 20 years of experiences, Duong Vinh Hoa never stops itself from updating and innovating to help bring QUALITY – CONVENIENT – ECO-FRIENDLY packaging solution to all customers.

(+84-272) 3900 228

Lot D20-D26, Road No. 3, Hai Son Industrial Zone, Duc Hoa Ha Commune, Duc Hoa District, Long An Province, Vietnam

www.dvhpackaging.com

© Copyright 2019 - DuongVinhHoa Packaging

Chính sách/ưu đãi sẽ được trình bày khi làm việc trực tiếp với khách hàng.