Printing : Gravure printing

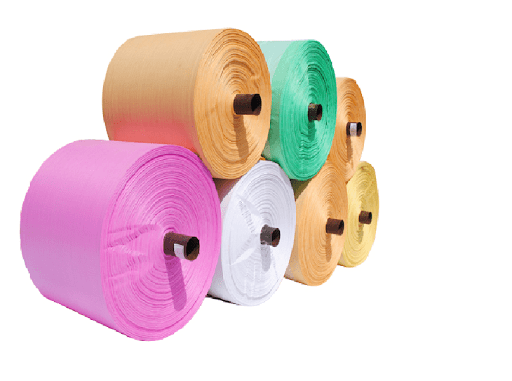

Material : PP + BOPP film

Sealing : Heat seal

Color : Many

Size : Custom

Samples : Yes

Weight : 70 gr – 150 gr, Custom

Lead time : 10-17 days after payment

Price : Contact for accurate pricing

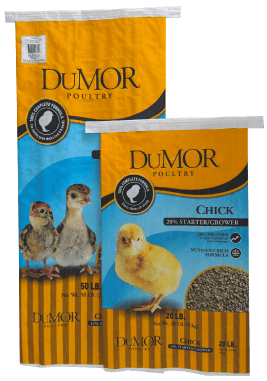

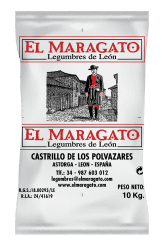

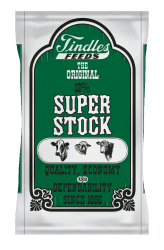

Application : Agricultural, construction and industrial product packaging

Customisation : Yes

Origin: Vietnam

MOQ : 30,000 – 40,000 pcs

Payment : L/C , T/T

Shipping : FCL, many

Certificate : HACCP , FSSC 22000 by Intertek, SEDEX SMETA 4P

QC : Tensile check, load check, print quality check

Supply ability :

BOPP / Kraft Laminated PP Woven Bags Back seam style: 250.000 sacks/day

BOPP / Kraft Laminated PP Woven Bags Tubular style: 130.000 sacks/day

Packaging & delivery : Normally 1000 pcs/ bale, can be customized

Port of loading : Ho Chi Minh City Port

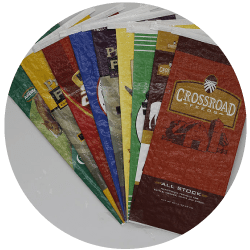

BOPP laminated PP woven bag is a high-class product sorted in PP bags category. Combined with gravure printing technology, this package is not only durable but can also be printed with any design according to your needs.

Specification:

Style:

The product is woven from colorless, odorless, tasteless PP plastic beads. This creates high mechanical strength to resisting effect of tearing force, pulling force, impacts etc.

Capacity load from 5kg-100kg, produce as customer's request. Capable of meeting needs of different product types.

The production process is professional, modern, conducted in accordance with standards and regulations. Thus creating uniform quality and durability.

Our large-scale factory containing more than 50 high-tech textile machines and multiple production lines. We can respond to large quantities orders quickly and on schedule.

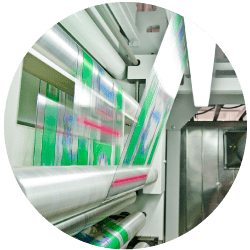

The gravure printing system with sharp, beautiful shadows. This helps improve the aesthetics, reinforce the trust and impression of customers .

The product compose of PP woven fabric + PP coated glue + BOPP film (w/ gravure printing)

There are two types of BOPP film:

PP fabric provides load bearing qualities

PP coated glue connects the film and fabric

BOPP film is printed on to create graphics but also prevent moisture absorption, reinforcing the product’s contents

Gravure printing technology is currently the modern printing method applied to printing, packaging, … especially BOPP gravure printing. The gravure printing machine can be used on all film materials, mixed laminates, providing customers high quality products.

BOPP gravure plastic packaging has been chosen and trusted by many customers. Duong Vinh Hoa apply this method to ensure customers would receive the highest quality products.

Stage 1: Printing BOPP film

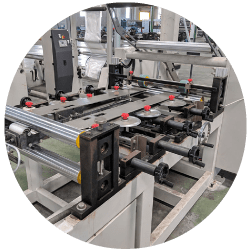

Stage 2: Coating the film with PP fabric

Stage 3: Cutting into parts

Stage 4: Sewing parts

Stage 5: Packing final products

After the manufacturing process, a tubular woven bag (without backing) is made up of a fabric woven by a circular loom. The woven fabric is cut to the right length thereby eliminating seams at the two edges of the bag.

Back woven PP bags have of no coated edges, which increase product aesthetics. The seams prevent the bag from falling and the EZ Open function allows the bag to easily open at the top.

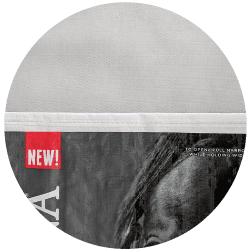

The design can be printed with up to 8-10 colours capable of providing sharp images. The lamination can be done with a matte or glossy finish. We can also do gravure print the front side and flexo print the back to cut costs for the client.

Depending to the customer's request, BOPP bags can come with or without handles.

By providing us one of the following options

Duong Vinh Hoa will produce to what you specify

Width minimum 30 cm,

Height maximum 120cm.

MOQ: 20.000 – 30.000 bags for each size/design

Shipment: FCL Shipment

With more than 20 years of experiences, Duong Vinh Hoa never stops itself from updating and innovating to help bring QUALITY – CONVENIENT – ECO-FRIENDLY packaging solution to all customers.

(+84-272) 3900 228

Lot D20-D26, Road No. 3, Hai Son Industrial Zone, Duc Hoa Ha Commune, Duc Hoa District, Long An Province, Vietnam

www.dvhpackaging.com

© Copyright 2019 - DuongVinhHoa Packaging

Chính sách/ưu đãi sẽ được trình bày khi làm việc trực tiếp với khách hàng.